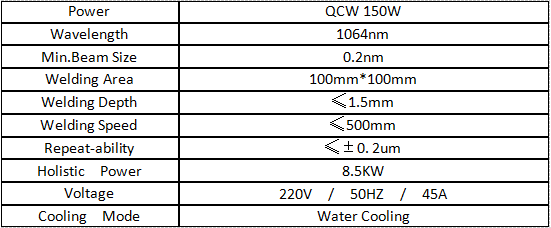

Technical Parameters:

Application:

Precise Welding For PC spindle and cellphone Frames and cellphone camera frame .

working Flows:

1.After the product is clamped onto a specific fixture, it is placed on the workstation of a four station workbench;

2.After placing it correctly, the operator presses the start buttons on both sides to start the equipment;

3.After 90 degrees of rotation, the product reaches the second workstation, which does not perform welding but only serves as a buffer before welding, And have the operator perform the clamping of the second set of welding products;

4.The operator restarts the equipment and the product reaches the third station, which is the welding station;

5.Welding begins while the operator clamps the third product;

6.After welding is completed and the third group of products is completed, the equipment restarts and the products return to the first station, and removal is completed Product and continue to place unwelded products;

Reviews

There are no reviews yet.