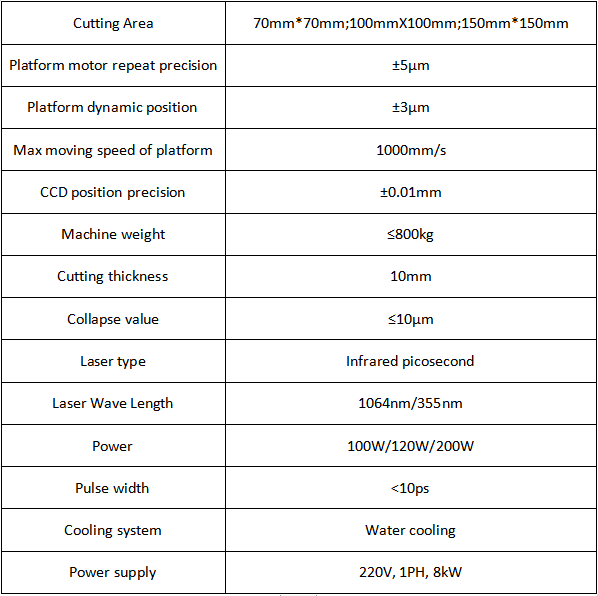

Technical Parameters:

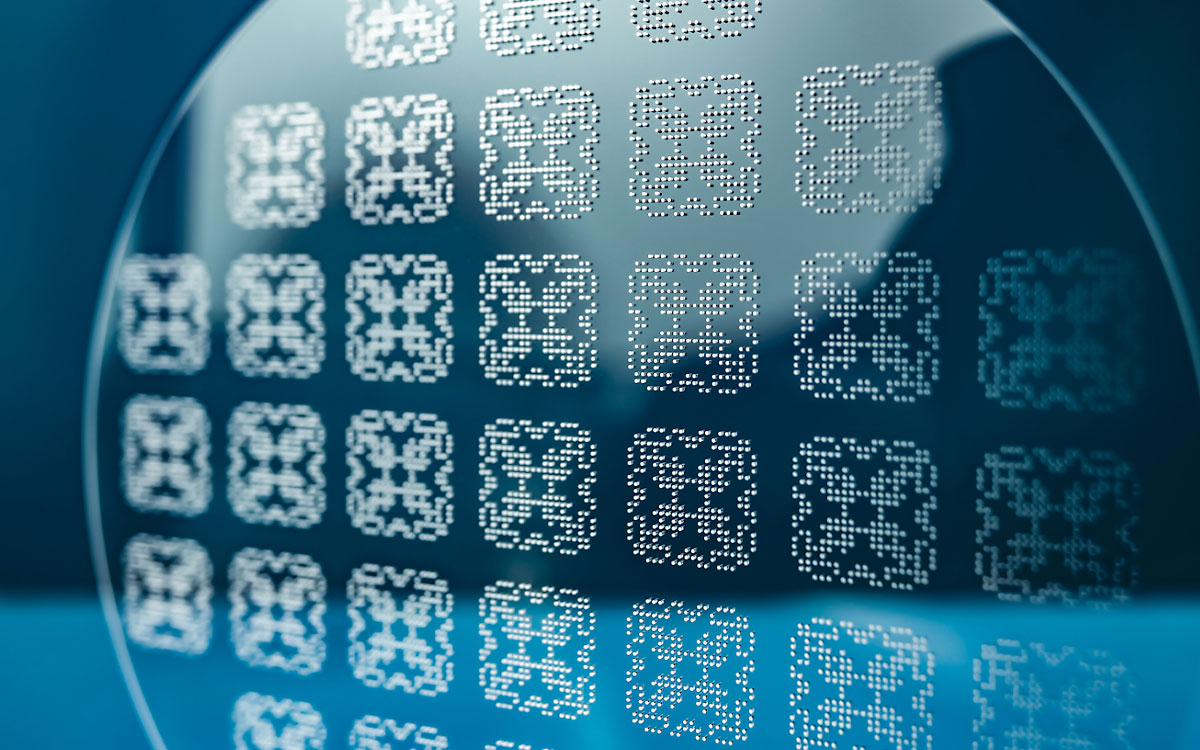

Application:

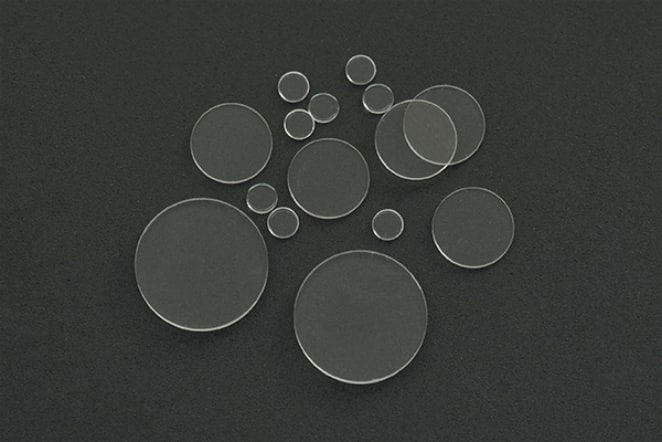

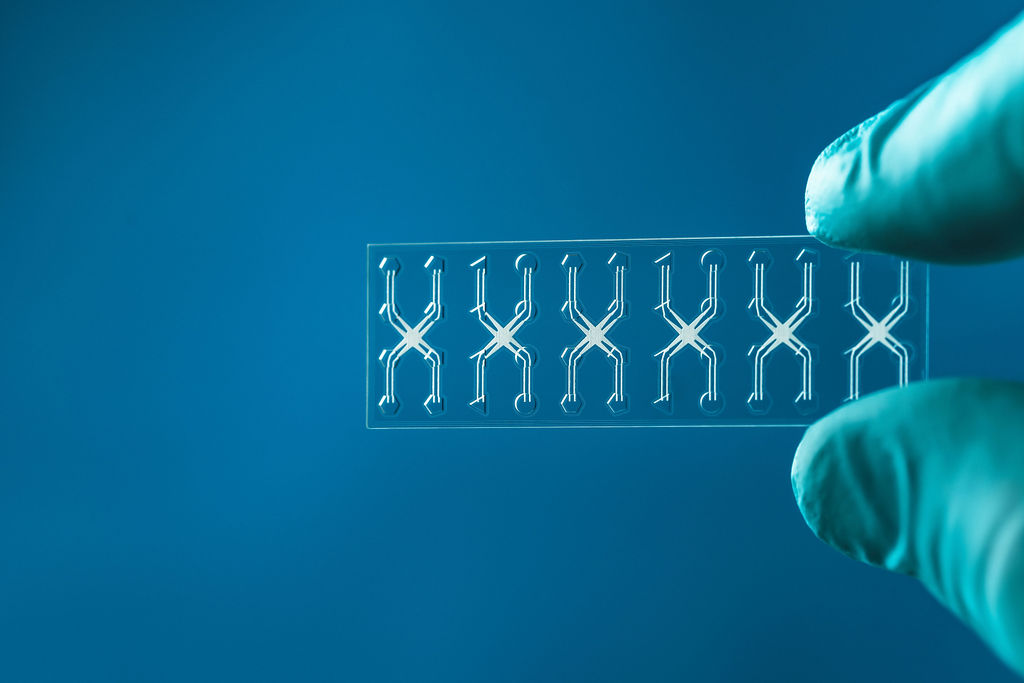

Widely used in automotive industry, construction industry, medical care, displays, sapphire, mobile phone cover glass, camera protection lens, home button cover, optical lens, etc. Rapid special-shaped cutting to large-sized filters used in large-scale manufacturing fields .

Working principle:

The laser beam’s high peak power and high peak power density are focused inside the glass, instantly vaporizing the material in the area to create a vaporization zone, which quickly spreads to the upper and lower surfaces to form holes. The cutting section is composed of countless hole points, and cutting is achieved through external stress fracture.

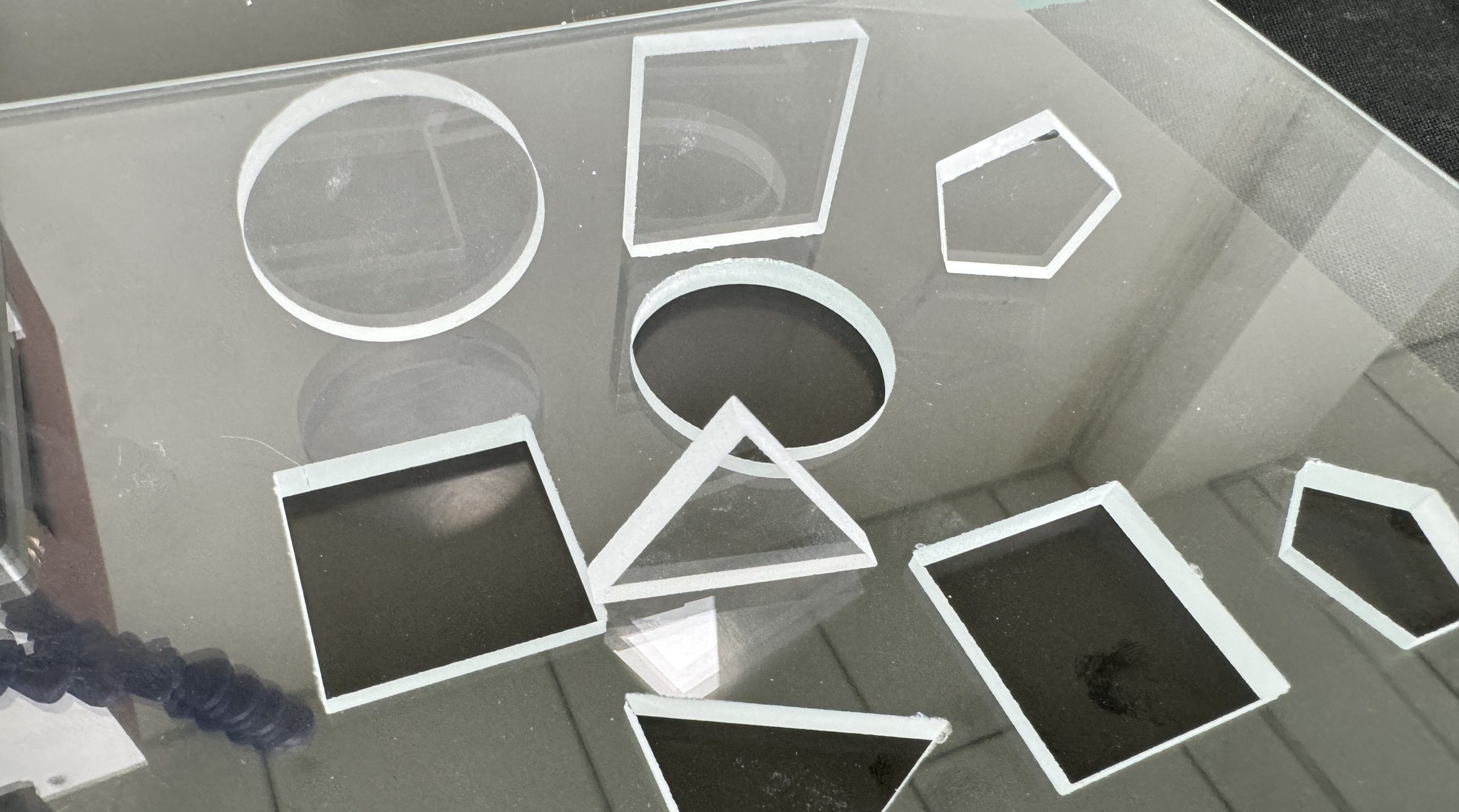

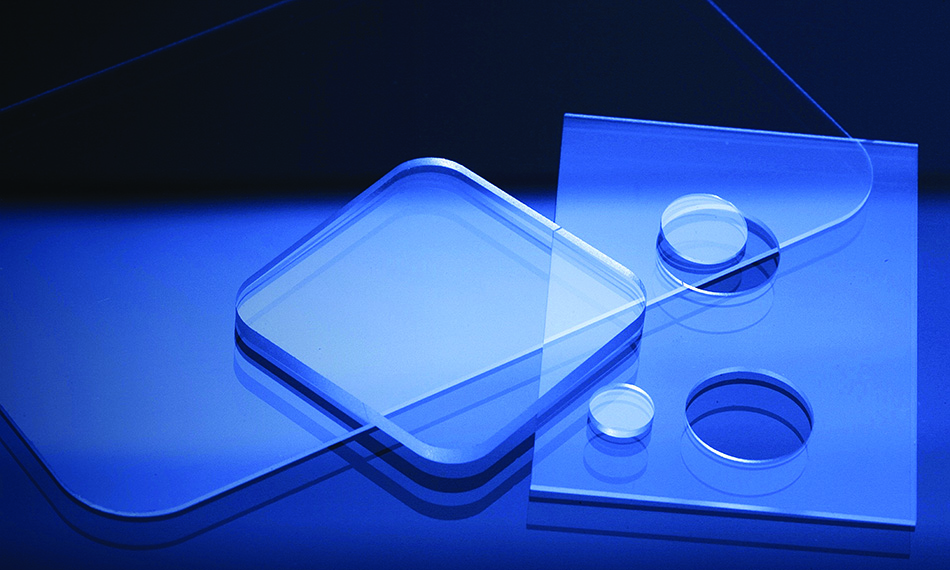

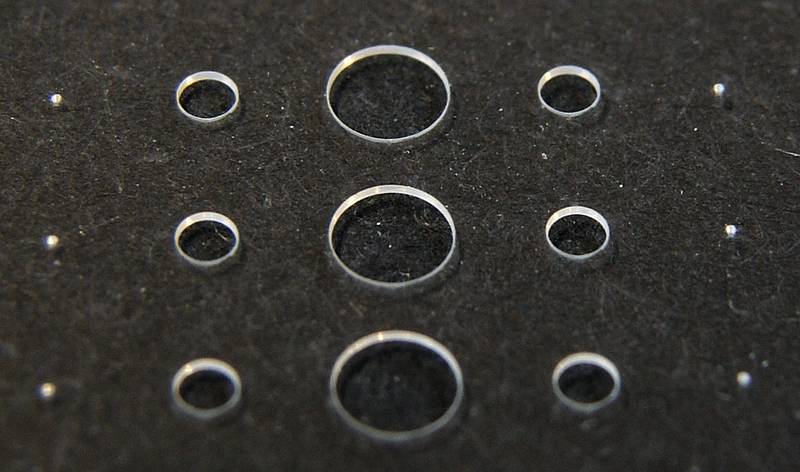

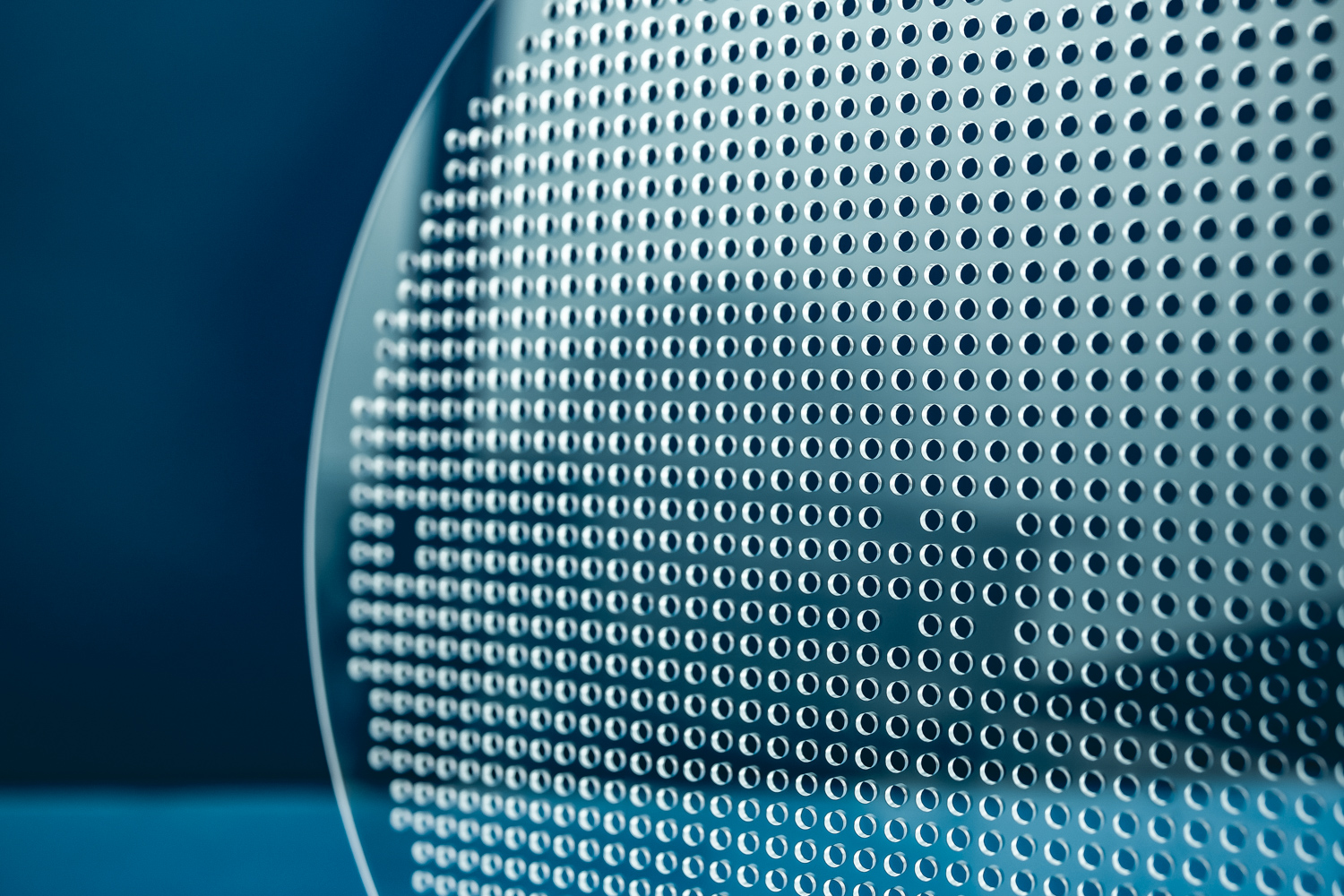

Samples:

Reviews

There are no reviews yet.