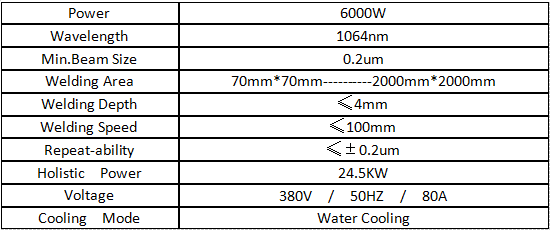

Technical Parameters:

working Steps:

1.The cylindrical battery cell assembly line includes: manual feeding, sorting machine, secondary scanning, manual shell insertion position, reserved automatic dispensing position, shared AI polarity detection scanning laser coding, manual placement of support nickel sheets, shared flipping laser welding machine, manual disassembly of fixtures, backend manual operation area, double speed chain line and other workstations.The assembly line for square shell battery cells includes: cell scanning and sorting, plasma cleaning, reserved dispensing stations, automatic sorting, manual gluing, module stacking, repair of upper and lower lines, module polarity detection, module pole addressing, CCS installation, shared flipping laser welding, post weld inspection, module EOL testing, module offline, and other stations.

2.The total length of the line is about 33.5 meters, with a total width of about 8.1 meters.The cylindrical assembly line is 9.4 meters long, 2.2 meters wide, and 2.2 meters high. The square shell line is 31 meters long, 7 meters wide, and 3.2 meters high

Reviews

There are no reviews yet.