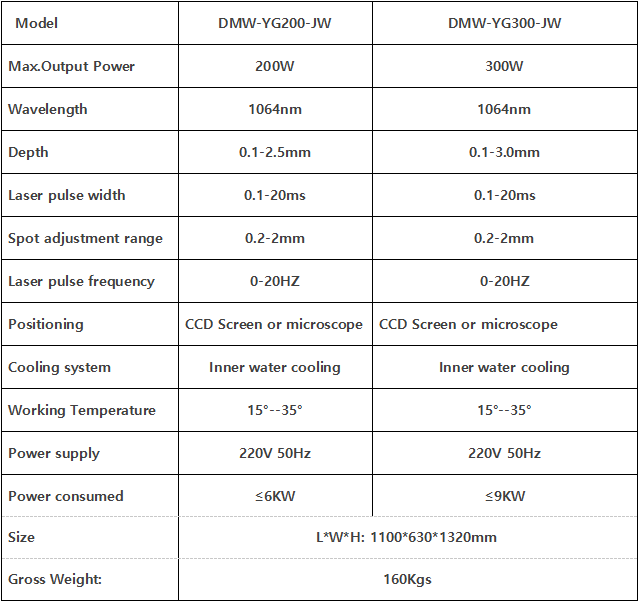

Specification:

Application:

1.The machine is mainly used for gold and silver ornaments of the fill hole and shops trachoma ,diamond and jewelry inlaying.

2.Widely used in spot welding of micro precision parts , such as batteries nickel belt , IC lead , watch springs , tubes , electron gun assembly and others .

3.This series laser welding machine widely applied to the material of gold, sliver , platinum , copper , aluminum , nickel , titanium , steel and so on .

Samples show:

Broken glasses laser welding dental laser welding jewelry Watch hairspring laser welding

Laser welding dental Laser welding broken glasses frame Laser welding jewelry Laser welding jewelry

Reviews

There are no reviews yet.